- Листовая экструзия

- Промышленность строительных материалов

- Экструзионная линия для производства водонепроницаемых мембранных листов из полиэтилена

- Экструзионная линия для производства водонепроницаемых мембранных листов ПВХ

- Линия экструзии листов водонепроницаемой мембраны ТПО

- Экструзионная линия для производства листов HDPE/PP с Т-образным захватом

- Экструзионная линия для производства полых листов ПК

- Экструзионная линия для производства толстых плит ПП, ПЭ, ПВХ, ПВДФ

- Промышленность новых материалов

- Промышленность термоформовочных материалов

- Линия экструзии листов PP PS

- Одношнековая экструзионная линия для ПЭТ

- Линия экструзии листов АБС

- Линия экструзии акрилового листа

- Линия экструзии листов ПК

- Линия двухшнековой экструзии листов ПЭТ

- Линия экструзии листов ламината TPU/TPO/ABS

- Линия экструзии оптических листов из ПММА ПК

- Экструзионная линия для термоформования листов HDPE

- Линия экструзии листов PLA

- Линия экструзии листов ПВХ

- Промышленность строительных материалов

- Трубопроводное прессование

- сплошной трубопровод

- Крупномасштабная линия экструзии HDPE

- Энергосберегающая высокоскоростная линия экструзии HDPE

- Линия экструзии трубы MPP

- Экструзионная линия для производства твердых труб из ПВХ

- Линия сплошных труб из ПВХ с двумя или четырьмя выходами

- PPR / PERT / PEX / Производственная линия экструзии трубопроводов холодной воды

- Силиконовые ядро трубки

- Купить сильфон

- Специальные трубки

- Нетрадиционные трубопроводы

- сплошной трубопровод

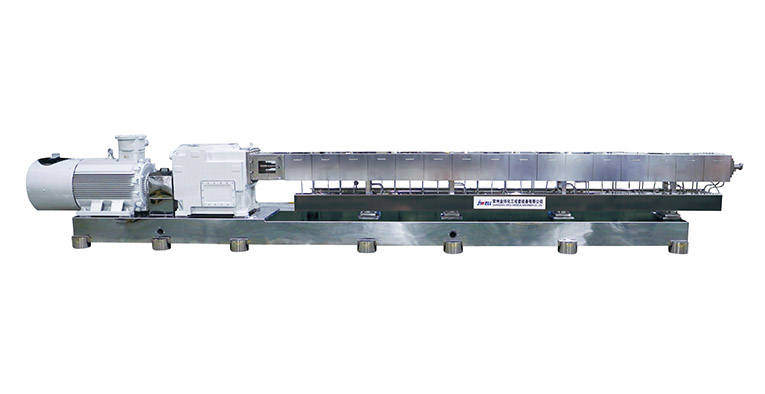

- Двухшнековый экструдер

- Другой

- проект

- Листовая экструзия

- 2017 Испания, проект по производству ПЭТ-листов производительностью 800 кг/ч.

- 2019 Италия, проект экструзии мембраны из полиэтилена высокой плотности толщиной 8000 мм.

- 2019 Россия, проект экструзии мембраны из полиэтилена высокой плотности толщиной 6000 мм.

- 2021 г., Китай, проект по экструзии листов из АБС-пластика производительностью 1200 кг/ч.

- 2022 г., Корея, проект по экструзии листов ПП производительностью 800 кг/ч.

- 2022 г., Таиланд, проект по экструзии листов ПП 700 кг/ч.

- Экструзия труб

- 2021 Турция 315 мм PE Высокоскоростные трубы экструзии

- 2021 Венгерский проект по экструзии медицинских труб

- 2022 Georgian 1000mm double wall corrugated pipe extrusion line

- 2022 Африканский проект экструзии 630 мм ПВХ труб

- 2022 Цзянсу 1200 мм высокоскоростной трубопровод экструзия

- 2023 г. Австралийский проект по экструзии четырехслойных гофрированных труб с двойными стенками.

- Двухшнековый экструдер

- 2019 Линия по производству малеинового ангидрида в России

- 2020 Португальская линия экструзии биополимеров кукурузного крахмала 1000 кг/ч

- 2021 Таиланд 800 кг/ч черная линия экструзии материнского материала

- 2021 Чехия 500 кг/ч комбинированная линия экструзии древесины и пластмассы

- Линия комбинированного экструзии со стекловолокном в российской лаборатории ПЭЭК ПГУ 2022 года

- Линия экструзии маточных материалов с высоким содержанием заполнителя 4 т/ч в Португалии 2023

- Листовая экструзия

- о нас